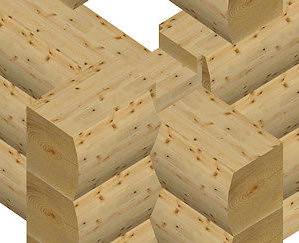

The field of log construction requires a flexible 3D CAD / CAM. First there is the single or multilayer composition of the wall with its complex corner joints and also often demanding fitting doors and windows. Log sections can vary from a rectangular log to a round log through to the D log or oval log. It should be noted that combinations of log walls and wood frame walls are increasingly implemented.

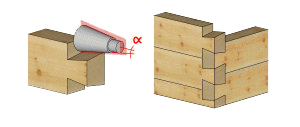

cadwork solves all tasks thanks to its Element module, including laps, slots, dado and other holes in a detailed and flexible way. After the automatic distribution of logs in a rough wall, each log, with its processes, can be directly exported to CNC machines or individual shop drawings. Conventional assemblies such as Tyrolean assembly or dovetail corner can be saved as a macro.

Due to the freedom of design, the shape of a log construction has no limit. Each log construction has its own touch and can still be completely designed and manufactured quickly.

Assembly lists are generated in one click and help define a unique position of each piece, showing the wall and the corresponding row. Groups and subgroups, allowing the distribution of parts in bundles, are automatically handled by the module.

Log wall shop drawings are automatically formatted according to the company's custom layout including assembly list numbers, production numbers and axes definition.

Thus manufacturing can start very quickly once the construction is modelled in 3D.